- Manufactured to conform to DIN and PS 15-69.

- 1 C-veil (30g/m2) + 2 Mat (450g/m2) 2.5mm (100 mil) resin rich corrosion liner.

- Hand laid, integral type construction, woven roving used continuously from flange face to hub for DN80 mm size and larger.

- Uniform external surface and stub outside diameter stub end surface prepared for immediate bonding.

- Bolt holes of drilled flanges are coated with resin.

- Flange holes drilling accoring to DIN 2501/PN10.

- Available in Vinyl Ester Resin, Derakane Momentum 411-350, 470-300 & Basic Vinyl Ester. Supply using other resin systems possible.

- MEKP cure system.

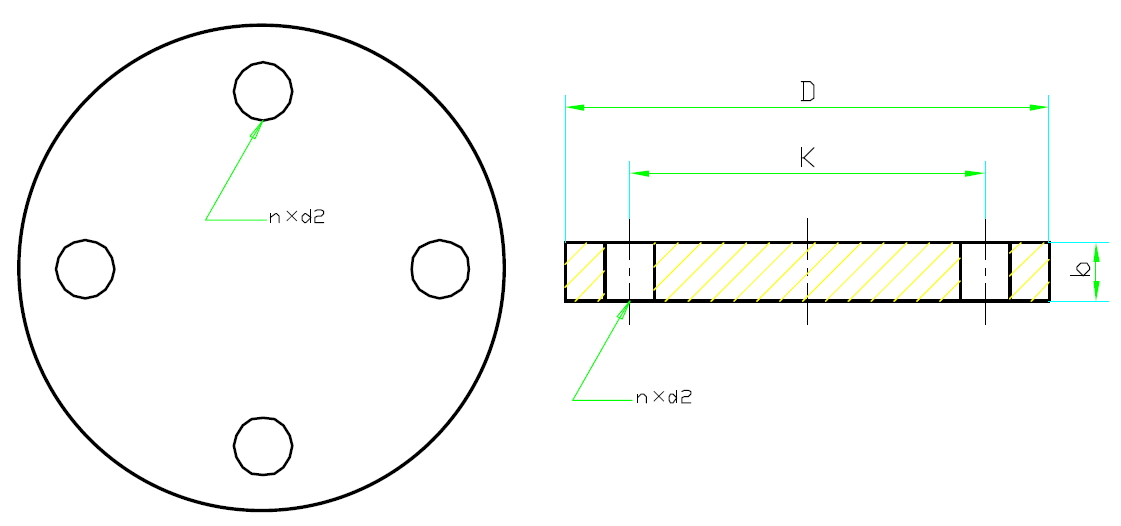

DIN Standard. (unit:mm)

| Flange Nominal | Working | Flange | Bolt Circle Diameter K (+/- 1) | No. of Bolt Hole Size n x d2 | Flange Thickness b (+/- 1) | Weight |

| DN25 | 16 | 115 | 85 | 4x14 | 15 | 0.26 |

| DN40 | 16 | 150 | 110 | 4x18 | 16 | 0.48 |

| DN50 | 16 | 165 | 125 | 4x18 | 18 | 0.65 |

| DN65 | 16 | 185 | 145 | 4x18 | 20 | 0.91 |

| DN80 | 16 | 200 | 160 | 8x18 | 22 | 1.17 |

| DN100 | 16 | 220 | 180 | 8x18 | 25 | 1.62 |

| DN125 | 16 | 250 | 210 | 8x18 | 27 | 2.25 |

| DN150 | 10 | 285 | 240 | 8x22 | 30 | 3.25 |

| DN200 | 10 | 340 | 295 | 8x22 | 32 | 4.94 |

| DN250 | 10 | 395 | 350 | 12x22 | 40 | 8.33 |

| DN300 | 10 | 445 | 400 | 12x22 | 44.5 | 11.77 |

| DN350 | 10 | 505 | 460 | 16x22 | 48 | 16.34 |

| DN400 | 10 | 565 | 515 | 16x26 | 51 | 21.74 |

| DN450 | 10 | 615 | 565 | 20x26 | 54 | 29.53 |

| DN500 | 10 | 670 | 620 | 20x26 | 57 | 34.16 |

| DN600 | 10 | 780 | 725 | 20x30 | 62 | 50.36 |